The Annual Wool Harvest

Wool is waterproof and durable. It is warm in winter and cool in summer. The annual wool harvest also known as sheep shearing is one aspect of wool production. Shearing usually takes place between April and June before the beginning of summer.*(1)

From the time the flock is herded into the corrals and until the wool is bagged and shipped for processing, there are many seemingly insignificant details, which, to one not familiar with wool production may seem unnecessary. For example, sheep need to be kept dry before shearing. Wet wool is harder to work with and damp wool can’t be bagged because it deteriorates. If rain or snow is in the forecast the flock is brought under cover the night (or day) before shearing. The floor is carefully swept prior to clipping the first sheep to keep the newly shorn fleeces free from debris that would devalue the wool.

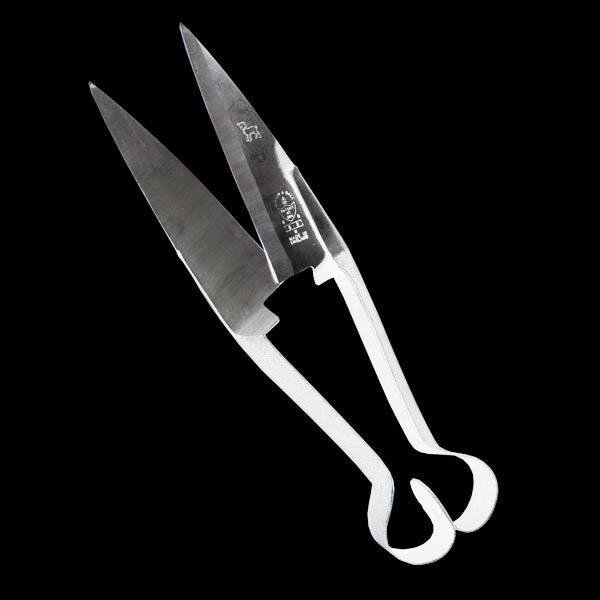

While most shearers use machine (power driven) clippers, there are still a few who use hand-powered blades. Modern blade shears are similar to the ones used by shepherds for centuries. Experienced hand shearers can clip about 100 sheep per day (depending on the size and weight of the sheep and condition of the wool). Sheep pastured on grass are cleaner than sheep sheltered in dirt and sandy corrals.

Hand Shearers are usually equipped with several pairs of blades and a wet stone, which are used to keep the edge of the blades sharp. The wool is not as sticky on warm days and is easier to clip. When wool grease collects over the blades they become gummy and less efficient. Shearers dip their blades in a container of water fastened to their shearing stands. Shearers cut from one side to the other in long sweeping motions so the fleece rolls off in one continuous blanket. They work swiftly, but carefully so they don’t nick or cut the skin. Hand shearing usually leaves a thin layer of wool on the sheep which is helpful where they need protection from the elements in chilly weather and to prevent sunburn. Research has also shown sheep with a thin layer of wool sheep (no more than an inch) are more comfortable on hot days since wool fibers dissipate heat more rapidly than sheep with less wool.

It is also important to avoid making a second pass over the same place known as second cuts. Second cuts result in short fibers reducing the value of the clip. Once the fleece is shorn from the sheep, low-grade wool also known as tags which are small, loose scraps (from legs, belly and face) are gathered and placed in a specific bin or wool bag. The wool is usually skirted (separate the high quality wool from any underbelly or stained wool). Once the low-value wool is removed the rest of the fleece is neatly folded into a close-fitting bundle and tied with paper twine. The fleeces are tied to make it easier to separate the clip into length and the various grades (texture defined by diameter of wool fiber, not length). Paper twine is used instead of synthetic fibers because it will wash out of the wool, while poly fibers as found in plastic twine will not. Once embedded in the wool foreign substances can be costly to remove. The fleeces are then tramped into large wool bags suspended on a sacking rack. Wool bags minimize dust and dirt contamination until the fiber is processed.

They work from one side to the other in long sweeping motions so the fleece rolls off in one continuous blanket – Hartnagle Ranch

Keeping colors grouped – black and spotted sheep are sheared last. Their fleeces are put in a separate bin. Any dark fibers (gray, black or brown) that get mixed into the white fleeces have to be removed by hand. Otherwise, even a few black fibers can flaw white or pastel-colored fabric.

Large wool producers generally market their wool directly to wool mills. Other wool growers sell their wool through various coops. Smaller flock owners may sell through coops, niche markets or merchandise directly to hand spinners depending on the type of wool. For a number of years we sent our wool to Baron Woolen Mills in Utah where the raw wool was cleaned*(2), dyed, carded, spun, woven *(3) into beautiful blankets. Baron was renowned for their blankets since the 1800s.

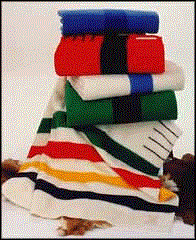

Following in the great western tradition of mountain men and rendezvous, Baron offered its authentic reproductions of centuries old designs, as well as its own authentic western era trader blankets.

Styled after one of the most popular blankets of the early traders, the Yukon was Baron’s highest quality, and most complex pattern to produce, requiring hand loading of the loom shuttles, in order to achieve the four different colored stripes.

Unfortunately, a large number of textile mills here in the United States including the Baron factory have closed or moved their facilities to foreign countries in recent years.

Notes:

*(1) – Some operations shear prior to their lambing season.

*(2) – Unwashed wool before scouring is known as grease wool.

*(3) – Only wool with good tensile strength (ability to withstand processing) can be used for blankets. Good tensile is directly related to the environment in which the sheep are raised, birthing, nutrition and wellness of the flock.

Copyright © 2009 – 2010 by Jeanne Joy Hartnagle-Taylor and Ty Taylor.

All Rights Reserved.

http://www.lasrocosa.com/education.html

Stockdog Savvy is a practical and useful handbook for ranchers as well as the hobbyist. If you want to learn to train stockdogs for farm and ranch work in the real world or for competition, this is the bookfor you. Almost 300 pages illustrated with diagrams and how-to photographs galore!

Stockdog Savvy also gives trainers, clinicians and judges an overview of many different herding dogs and types of livestock. It is the quintessential guide to owning, training, trialing, working or caring for your stockdog.

Additionally, people who don’t have access to livestock can teach all the basic herding commands through play training. Herding skills taught in a game format are fun activities to keep dogs in the city mentally and physically fit.

The Table of Contents:

Frontispiece: Just a Stockdog Story

Preface

Foreword by Ernie Hartnagle

Introduction

1 – HERDING DOGS

2 – WHAT TO LOOK FOR IN A HERDING DOG

3 – PREPARING YOUR PUPPY

4 – LAYING THE FOUNDATION

5 – GETTING STARTED

6 – INTRODUCING A DOG TO STOCK

7 – MAKING THE MOST OF YOUR DOG’S TALENT

8 – DEVELOPING A USEFUL DOG

9 – THE OUTRUN

10 – DRIVING SKILLS

11 – BALANCE AND PENNING

12 – FOCUS ON SORTING

13 – BOUNDARY TRAINING FOR TENDING DOGS

14 – BASIC STOCKMANSHIP

15 – WORKING LARGE FLOCKS AND HERDS

16 – THE RANCH DOG

17– TRAINING ANIMALS

18 – POULTRY

19 – SHEEP

20 – GOATS

21 – CATTLE

22 – KEEPING LIVESTOCK

23 – THE TRIAL DOG

24 – TRIAL PROGRAMS

25 – WHAT JUDGES LOOK FOR

26 – OTHER ELEMENTS OF WORKING STOCKDOGS

Appendix -– BREED PROFILES

For more information please visit:

http://www.lasrocosa.com/education.html

Copyright © 2009 – 2010 by Jeanne Joy Hartnagle-Taylor and Ty Taylor.

All Rights Reserved.